Do you ever feel like you’re working twice as hard but barely seeing the financial reward? Or maybe you struggle to explain your pricing when a customer raises an eyebrow at your rates?

These are challenges nearly every independent welder faces. You want to be fair, but you also need to make a living. You want to grow, but unexpected material costs, fluctuating fuel prices, and time-consuming job estimates keep cutting into your profits.

So, how do you ensure your pricing covers expenses without losing clients? What’s the secret to streamlining operations without cutting corners? And how can you build a loyal customer base that keeps your business moving?

In this blog, we’ll dive into the strategies that successful welding professionals use to overcome these hurdles.

1. Setting the Right Pricing Strategy

One of the biggest questions for welding professionals is how to price their services. Should you charge a flat rate, hourly rate, or mark-up materials?

Here are a few essential considerations:

- Material Markup: A fair markup on materials ensures profitability while covering unexpected costs. Many welders charge a 15% markup for individuals and a 20% markup for larger businesses to account for taxes, delivery, and procurement time.

- Service Fees & Hourly Rates: Charging a flat service fee (e.g., $250 per job) can help cover overhead costs such as fuel, consumables, and equipment maintenance. Fieldwork rates vary but typically fall between $100–$150 per hour, depending on experience and location.

- Offering Flexible Pricing for Individuals: Some welders choose to offer lower shop rates (e.g., $65 per hour) for individual customers to remain competitive while still making a profit.

What should you do: Research your competitors’ pricing and consider offering tiered pricing based on the type of client (individual vs. business). Transparency in pricing builds trust with customers.

2. Managing Costs Without Cutting Corners

Keeping costs low while maintaining high-quality work is key to running a profitable welding business. Smart material purchasing plays a big role, buying in bulk whenever possible helps cut costs, and maintaining strong relationships with suppliers can lead to discounts and priority service. Every dollar saved on materials adds up over time.

A DIY approach can also go a long way. If you have the skills, handling certain non-welding tasks yourself, like building your own equipment storage or workbenches can reduce overhead without compromising efficiency. Additionally, keeping track of resources like welding rods, gas cylinders, and other consumables prevents unnecessary waste and ensures better cost control. The more efficiently you use what you have, the less you’ll spend on replacements.

To stay profitable while keeping pricing competitive, detailed record-keeping is key. Tracking material costs, labor, and overhead expenses gives you a clear picture of where your money is going and helps you set fair, sustainable rates for your services.

3. Balancing Customer Service and Profitability

Customer satisfaction plays a crucial role in the success of a welding business. Being fair with pricing and offering flexible payment options can go a long way in building loyalty. Fair pricing and flexible payment options build trust and loyalty, making clients more likely to return and refer others.

Many welders find that being upfront and honest about pricing pays off. Customers appreciate a welder who charges fairly, and some professionals even let clients decide what they think is fair for minor repairs. This level of transparency strengthens relationships and fosters repeat business.

Word-of-mouth marketing is one of the most powerful tools in a welder’s arsenal. Happy customers naturally spread the word, reducing the need for paid advertising. In fact, studies show that 92% of consumers trust recommendations from friends and family over traditional ads. Providing excellent service at a fair price can create a steady stream of referrals that cost you nothing.

Small jobs can be tricky to price, but many welders take a flexible approach, charging based on effort rather than a strict hourly rate. This keeps customers happy while ensuring that even quick fixes are worth your time. Offering transparent pricing and the occasional goodwill gesture—like discounted rates for repeat clients or small-value services as a courtesy—can go a long way in building customer loyalty.

4. Streamlining Operations for Maximum Efficiency

A well-organized workflow is the backbone of any successful welding business. Scheduling jobs strategically based on complexity and material availability helps avoid delays and keeps projects moving smoothly.

Investing in high-quality tools may require a higher upfront cost, but it saves money in the long run by reducing downtime and repair expenses. Durable equipment means fewer breakdowns and more consistent performance.

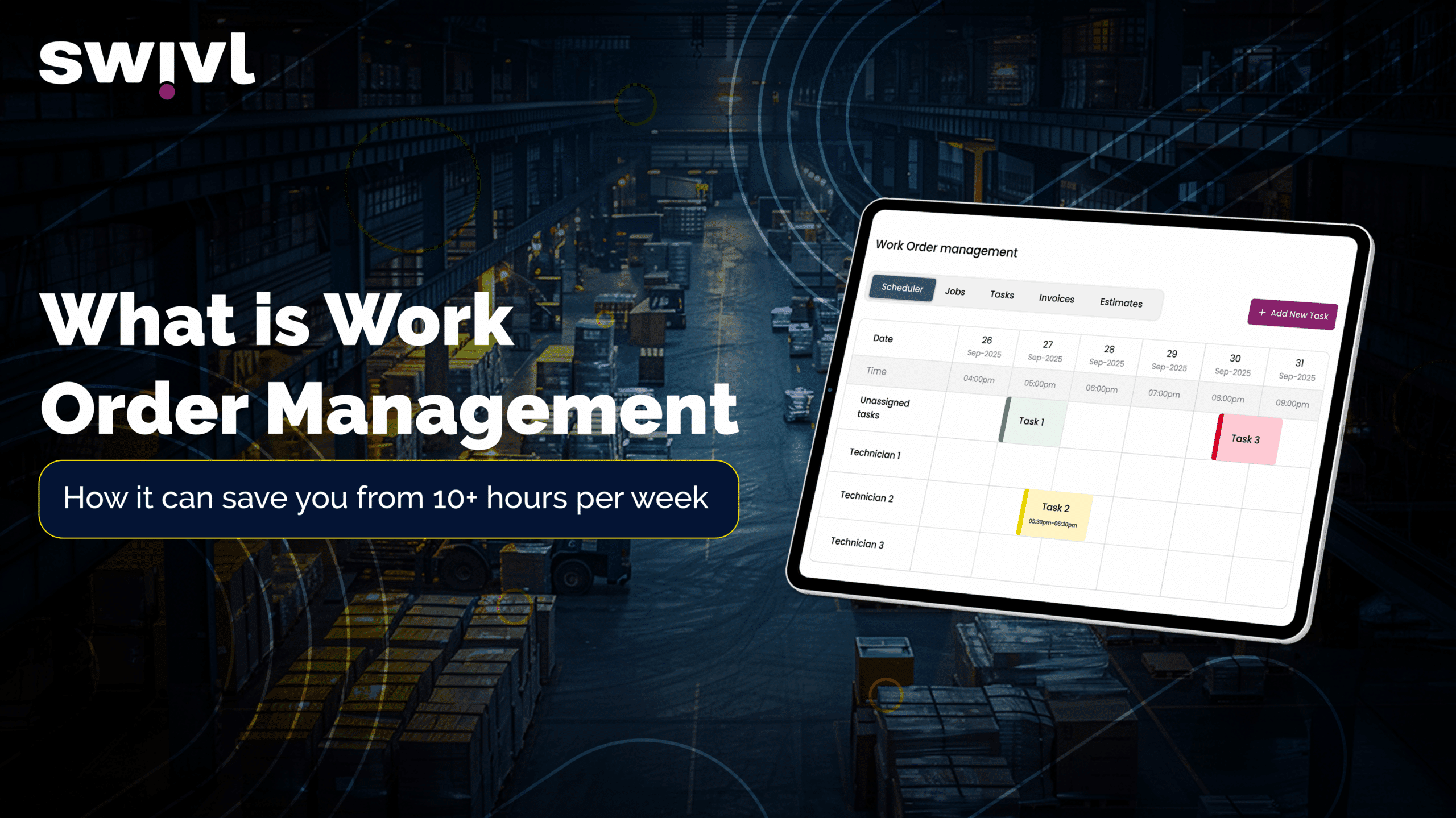

Tracking income and expenses isn’t just about balancing your books it’s about planning for growth. Proper bookkeeping helps identify profit trends, manage cash flow, and prepare for future investments. Digital tools can make this process even easier. Using online invoicing, job scheduling software and digital payment options minimizes paperwork and speeds up transactions, giving you more time to focus on your craft.

If administrative tasks are eating up too much of your day, consider automating them. Digital solutions streamline operations, making it easier to manage invoices, track jobs, and keep everything running efficiently. Less paperwork, fewer headaches, and more time for welding that’s a win.

5. Overcoming Common Challenges in the Welding Industry

Like any trade, welding comes with its fair share of challenges. One of the biggest hurdles is the rising cost of fuel and equipment. Factoring in these expenses when setting your rates ensures that you’re covering costs without underpricing your services.

A lot of welders make the mistake of only accounting for materials and labor, but wear-and-tear on equipment and travel costs should always be part of the equation.

Non-paying customers can also be a major setback. To avoid unpaid invoices, setting clear payment terms upfront is a must. For larger projects, requesting a deposit before starting work provides a layer of financial security. This ensures that even if a client delays payment, you’re not left covering all the costs yourself.

Lastly, work-life balance is something every welder struggles with at some point. Long hours and demanding projects can lead to burnout if you’re not careful. Setting boundaries—like designated days off or limiting weekend work—helps maintain energy and enthusiasm for the job. Taking time to recharge isn’t just good for you; it’s good for business, too. A well-rested welder is a more productive one.

Final Thoughts

Running a successful welding business requires a combination of fair pricing, efficient cost management, strong customer relationships, and streamlined operations. By implementing these strategies, welding professionals can improve profitability while maintaining a loyal customer base.

Whether you’re just starting or looking to optimize your existing welding business, taking a structured approach to price, resource management, and customer service can help set you up for long-term success.